Although the national and European political-strategic agenda was by now directed towards decarbonization scenarios to be concluded within a few years, the well-known international crisis in the energy sector has forced the temporary return to the use of solid fossil fuels, and in some cases to low volatile carbons even up to the end of the current decade.

Some producers, in the intention of avoiding possible problems in the management of their thermoelectric units, have decided , in the current contingency , to improve the boiler combustion performances by conveniently balancing the level of unburnt products in the fly ash and NOx emissions. Moreover, if, despite the best actions aimed from improving the combustion conditions by falling within the permitted emission parameters, the characteristics of the available coal is such as to induce the level of unburnt products to be exceeded, it will be inhibiting the delivery of fly ashes in the dry state to the cement plants.

Consequently it is necessary to have a discharge of humidified fly ash for transport them to landfills. From this need arises the requirement to give maximum reliability to the wet extraction, dosing and humidification process also considering to minimize dirty water dispersion in the sewage system of the power plant or during truck transport..

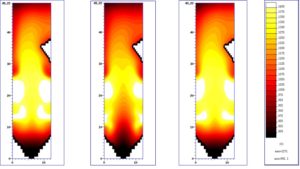

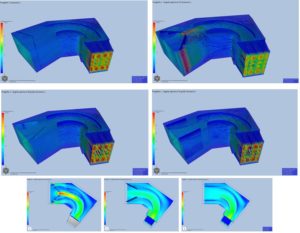

At the same time, considering the very high cost of landfilling, it was deemed appropriate to further study the effects on combustion of the various secondary air distribution arrangements along the various inlets of the combustion chamber; in fact, this study determines the ideal set-up for the right balance of UBC and NOx. It is known that good coal combustion is influenced by many parameters, the main ones being the fineness of the grinding and an adequate distribution and orientation of the secondary air along the various inlets from the air boxes to improve mixing of the fine powder with the comburent air while minimizing the production of thermal NOx.

Industrial Engineering Services S.r.l. already operating in the thermoelectric production sector for many years and considerably enhanced thanks to the collaboration of former managers and technicians from the ENEL combustion sector, it was commissioned by an important player to study all the set-up actions necessary to deal with the contingent situation .In particular, the assignment ranges from the restructuring of the wet fly ash discharge system with the introduction of volumetric dosing systems for ash and water, to fluid dynamic surveys, CFD simulations and consequent secondary combustion air regulation hypotheses at various levels of tangential combustion chamber with the aim of minimizing UBC and NOx emissions consequent to the use of low volatile coals. In this scenario, the team of experts deployed for this purpose operated having at their disposal the specialized instrumentation of Industrial Engineering Services S.r.l. laboratory. and related CFD simulation services.